Fabrication rise with us

Our capabilities

"VCare Engineering is a leader in fabricating unit static equipment for process industries. Established in 2005, VCare Engineering Manufactures the entire range of process equipment for end-users in core industry segments like Oil & Gas, Refineries, Petrochemicals, Fertilizers, Energy, Power, Water, Chemicals, Fertilizer, FMCG, Cryogenic and Pharmaceutical industries around the world. It is engaged in the design, engineering and fabrication of heat exchangers, pressure vessels, columns and other heat transfer equipment used in critical High-Temperature and High-Pressure processes. For Heat Exchangers, a separate in-house engineering team comprising of design engineers with core design experience in all kinds of Shell & Tube Heat Exchangers undertakes all thermal and mechanical design of equipment.

We have manufacturing facilities located in Manjusar, Savli GIDC in Vadodara district of Gujarat state.

Our facility is accredited with the following certifications: ISO 9001-2015, ISO 45001-2018 , ASME 'U', 'NB' , 'R',

We have technological tie-ups with CHART Inc, USA (Previously HUDSON Products, USA) for Finned Fans and Fan Blades and with Born Heaters for Fired Heaters Components which we manufacture at our premises.

The VCare Engineering - Manufacuring Division has a large, highly skilled workforce. Skilled workmen and trained, competent and highly committed people have repeatedly been able to channelise the knowledge and experience that VCare Engineering has gained over the years, through its robust systems, to ensure that projects are successfully executed on time.

Our core expertise of design and manufacture is driven by creativity and innovation and backed by over 15 years of experience. Improving efficiency and cost-effectiveness is our ongoing endeavour.

Through continuous improvement in quality, a deep commitment to on-time delivery and a clear policy of keeping in step with the latest manufacturing technology, VCare Engineering is fully equipped to meet the challenging demands of its global customers for process equipment.

Health, Safety and Environment are the corner stones around which the VCare Engineering manufacturing is built."

Products & Services

"VCare have productline that matches with every requirement of process industry to include but not limited to following products:

- Pressure Vessels, Reaction Vessels & Other Vessels

- Technological Process Equipment

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers/Condensers

- Silos, Hoppers

- Shop Fabricated Tanks

- Process Skid Packages/Modular Process Plants

- Structures

- Custom Built Equipments

- Columns & Towers

- Dosing Packages

- Cryogenic Systems

- Direct Fired Heaters & Components

- Waste Heat Recovery units

- Pig Receiver & Launcher

- Incinerators

- Louvers

- Utility Packages

- Heater Treaters

- LNG Vessels"

Certifications

"VCare have achieved following Certificates that speak volumes of our commitment to quality of our deliveries -

- ISO 9001:2015

- ISO 45001:2018

- ASME ""U"" Stamp

- ASME ""R"" Stamp

- ASME ""NB"" Stamp"

Manufacturing

"VCare Engineering has state of the art fabrication shop dedicated to manufacturing of Heavy, Medium & Light equipment. VCare Engineering manufactures critical equipment of : Diameter: up to 4 meter Length: up to 50 meter"

Design

"The Design team of Vcare Engineering comprises of qualified & experienced design engineers & draughtsmen well versed with Indian & International codes. This enables us to design & fabricate the most complicated process equipment meeting the process conditions & fabrication standards. Experience in various design standards... Mechanical Design as per -

- ASME Sec. I

- ASME Sec. III

- ASME Sec.III NB

- ASME Sec. VIII Div. 1

- ASME Sec. VIII Div. 2

- ASME Sec. VIII Div. 3

- ASME B 31.3

- API 660

Welding

"Our welding engineering utilises qualified procedures for an extremely wide variety of metallurgies. Welders capable of welding in XG welding positions, have been qualified under reputed inspection agencies like HSB, TUV, Lloyds, BVIS, etc.

Our welding engineers have developed Efficient welding processes for internal bore overlaying of small internal diameter, tube-to-tube sheet welding by orbital TIG, long seam welding on long seamers, nozzle welding, strip cladding by SAW and Electroslag processes, narrow gap welding for thick circ-seam and long- seam joints.

Metallurgies we specialise in are:

Carbon Steel:

IS 2062, SA 516 Gr. 60/70 (N/HIC/NACE/LTCS), SA-105N, SA-266 CL-2, SA266 CL-4, SA-350 LF2, SA-106 Gr B, SA333 Gr 6, SA53 Gr B, API – 5L etc.

Stainless Steel:

SA240 TP 304/304L, SA240TP 316/316L, SA240 TP 321, SA240 TP310, UNS31803 (Duplex) UNS32750 (Super Duplex), SA312 TP 304/304L, SA312 TP 316/316L, SA312 TP 321, SA312 TP 310, SA182 F304/304L, SA 182 F316/316L, SA366 F1, SA366 F5, SA366 F11

Low Alloy Steel:

SA 387 Gr P-11,SA387 Gr P-9, SA387 Gr P-5, SA387 Gr P91

Special Grade Material:

CuNi 90/10 (C70600), CuNi 70/30 (C71500), SB111 C70600, SB111 C71500, Hastelloy C270, Titanium, Monel UNS4400, AL 6061 T6, AL 5083, SB241 5083-O"

Quality

VCare has stringent quality control procedures and documentation system that is certified as per ISO 9001:2015. Following photographs to be inserted:

- Cleaning room, NDT, equipment, Machineries, etc.)

- Facility details

- U & R Stamp certificates

Shell & tube heat exchangers

Application:

- Oil Refineries

- Oil cooling

- Preheating

- Steam generation

- Boiler blow down heat recovery

- Vapour recovery system

- Industrial paint systems

Benefits:

- Designed to bear high pressure

- Flexible and steady design

- Flexible design to bear very high as well as very low temperature

- Resistant to thermal shocks

- Practically no dimensional limits

Air cooled condensers

Application:

- Combined cycle power plants

- Captive power plants

- Steam power plants

- Air conditioning applications

- Distillation processes

- Concentrated solar plants

- Biomass & waste to energy plants

Benefits:

- Simple in operation

- Comparatively smaller in size

- Low maintenance requirement

- Easy to clean

- Lesser complex design

Modular / skid mounted units

Application:

- Cryogenic service industry

- Oil & gas plants

- Food processing industry

- Petrochemical plants

Benefits:

- Re-locatable

- Flexibility in acceptance testing

- Smaller footprints

- Added level of protection

- Modularity

- Affects the project completion time

Columns & towers

Application:

- Distillation

- Stripping

- Absorption

- Adsorption

- Extraction

Benefits:

- Helps in refining the oil / media

- Separation of chemical components from oil / media

- Removal of inorganic compounds

- Removal of other nuisance particles

Pressure vessels

Application:

- Petrochemical plants

- Pharmaceutical

- Oil & gas

- Nuclear power industry

- Biotechnology

- Food industry

Benefits:

- Holds elements at specific pressure levels

- Stores liquified gases

Wastewater treatment plants

Application:

- Primary, secondary + tertiary sewage treatment.

- Incineration/ odour control + methane recovery- sludge treatment.

- Disinfecting process purifies raw sewage.

- Safety in wastewater treatment facilities.

- Monitoring of oil and petrol separators.

Benefits:

- Provides clean and safe water

- Savings of money

- Beneficial to the environment

- Waste reduction

- Water conservation

- Improved sustainability

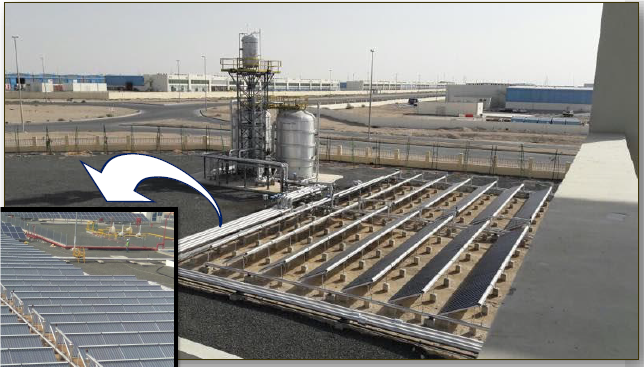

Solar thermal plants

Application:

- Space heating

- Air conditioning

- Industrial process heating

- Drying

- Distillation & Desalination

Benefits:

- Provides clean and safe water

- Savings of money

- Beneficial to the environment

- Waste reduction

- Water conservation

- Improved sustainability

Air cooled heat exchangers

(Technology tie-up with Hudson Corporation, USA)

Application:

- Process media cooling

- Process media condensation

- Distillation & refinement

Benefits:

- Requires low maintenance

- Low operating cost

- Independent equipment

- Lesser energy consumption

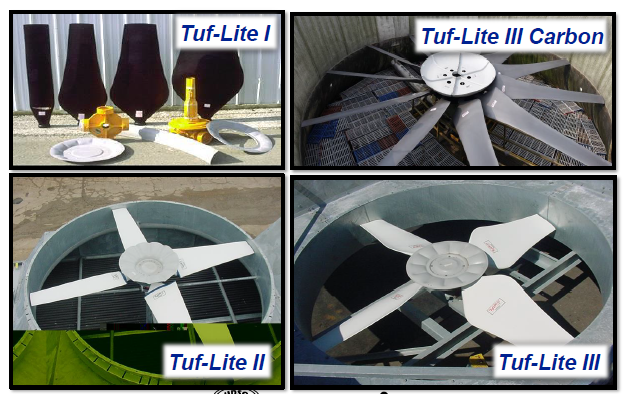

FRP Aerodynamic fans for cooling towers & air coolers

(Technology tie-up with Hudson Corporation, USA)

Application:

- Cooling towers

- Air cooled condensers / Air Cooled Heat Exchangers

Benefits:

- Aerodynamic impellers

- Weight reduction compared to other material of fans

- Need lighter duty bearings

- Lesser power consumption

- Noise reduction

- Durability

- Fire safety

Industrial silencers ( Blow off silencers - Pipe / inline silencers - Resonance silencers - Baffle silencers )

(Technology tie-up with w&p Noiseprotection, GmbH)

Application:

- Blowers

- Compressors

- Boilers

- Relief valves

Benefits:

- Absorbs inlet and exhaust noise

- Reduces noise vibrations

- Reduces noise pollution

- Protects the environment and individuals from heavy noise