Global Presence

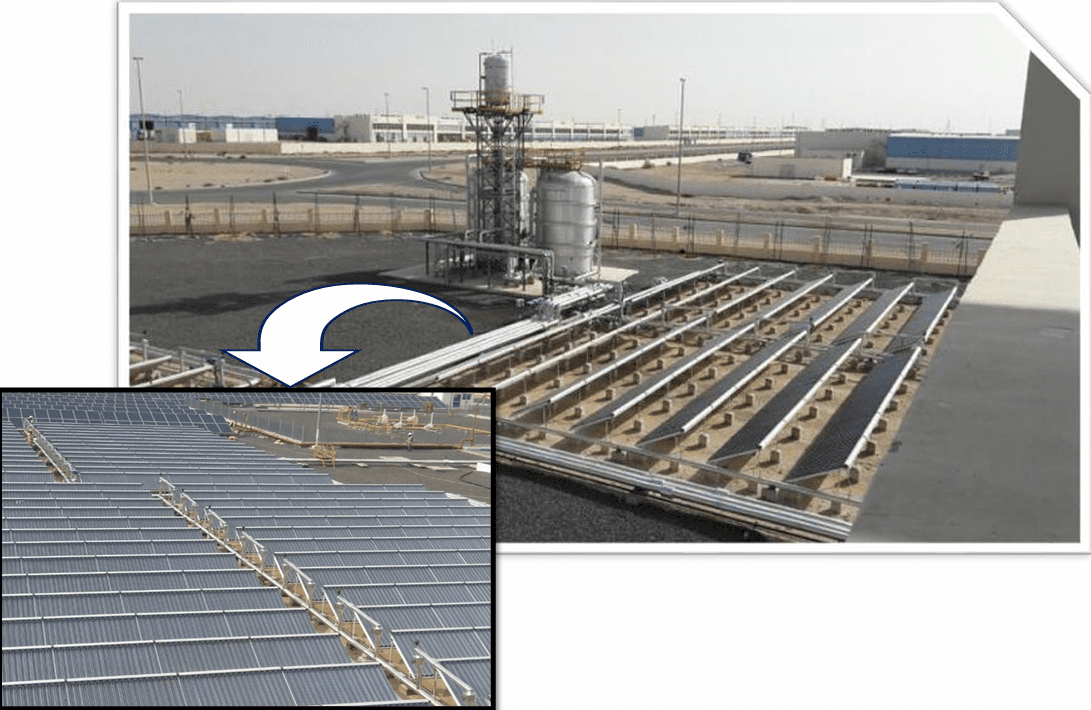

We serve a global clientele, with projects successfully delivered worldwide. Our engineering team, manufacturing setup and unmatched logistics expertise are capable to comply with international standards and complex shipping requirements for design, manufacture and delivery to clients, wherever they are.

A few highlights of our global project executions:

- Support design calculation and modelling of pipes, E & I for LNG project of Russia (as per Russian Standard).

- Vessels and heat exchangers designed and supplied to the USA and Nigeria (as per ASME "U" stamp).

- Sulfuric acid railway containers designed and supplied to Australia (with WorkSafe design certification).

- Modular skid based oxygen plant supplied to Spain (compliant to oxygen cleaning).

- Vessels and heat exchangers designed and supplied to Austria with CE marking (as per AD 2000 and PED standards).

- Vessels and heat exchangers designed and supplied to Canada (with CRN certification).

- Titanium equipment designed and supplied to Canada (compliant to SCOMET requirements).

- Equipment designed and supplied as per IBR (Indian Boiler Regulation).

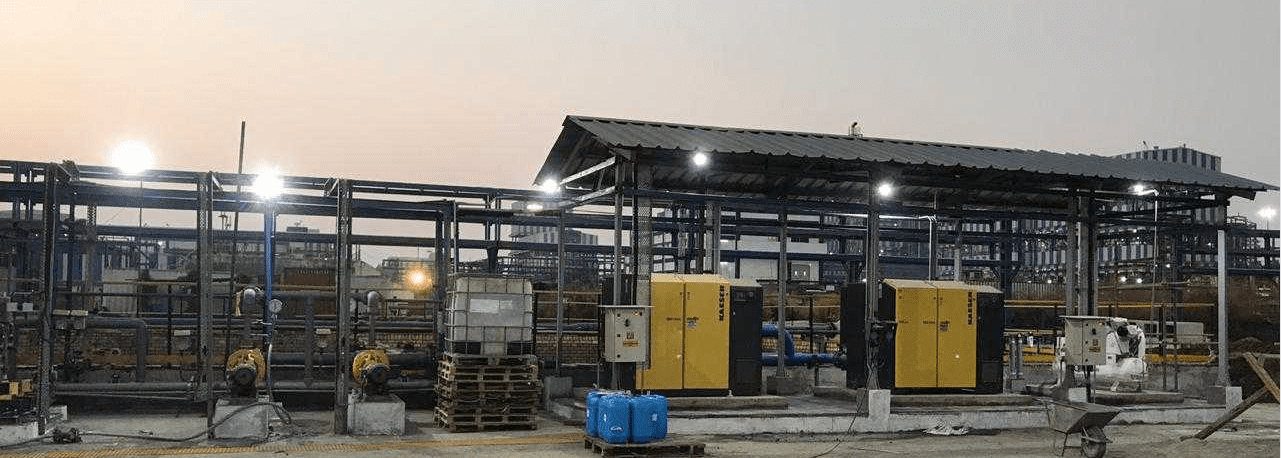

Our Facilities

Our state-of-the-art manufacturing facility is equipped to handle projects of significant scale and complexity, ensuring quality control at every stage.

- Main workshop size: 200m L x 25m W x 25m H x 18m Hook height

- Open bay size: 5,000 sq. meters with 100-ton crane access

- Office details: 500 sq. meters of modern office adjacent to workshop

- Clean room facility for fabrication of special alloy equipment

- Dedicated material store with advanced inventory management

- Climate-controlled painting booth for specialized coatings

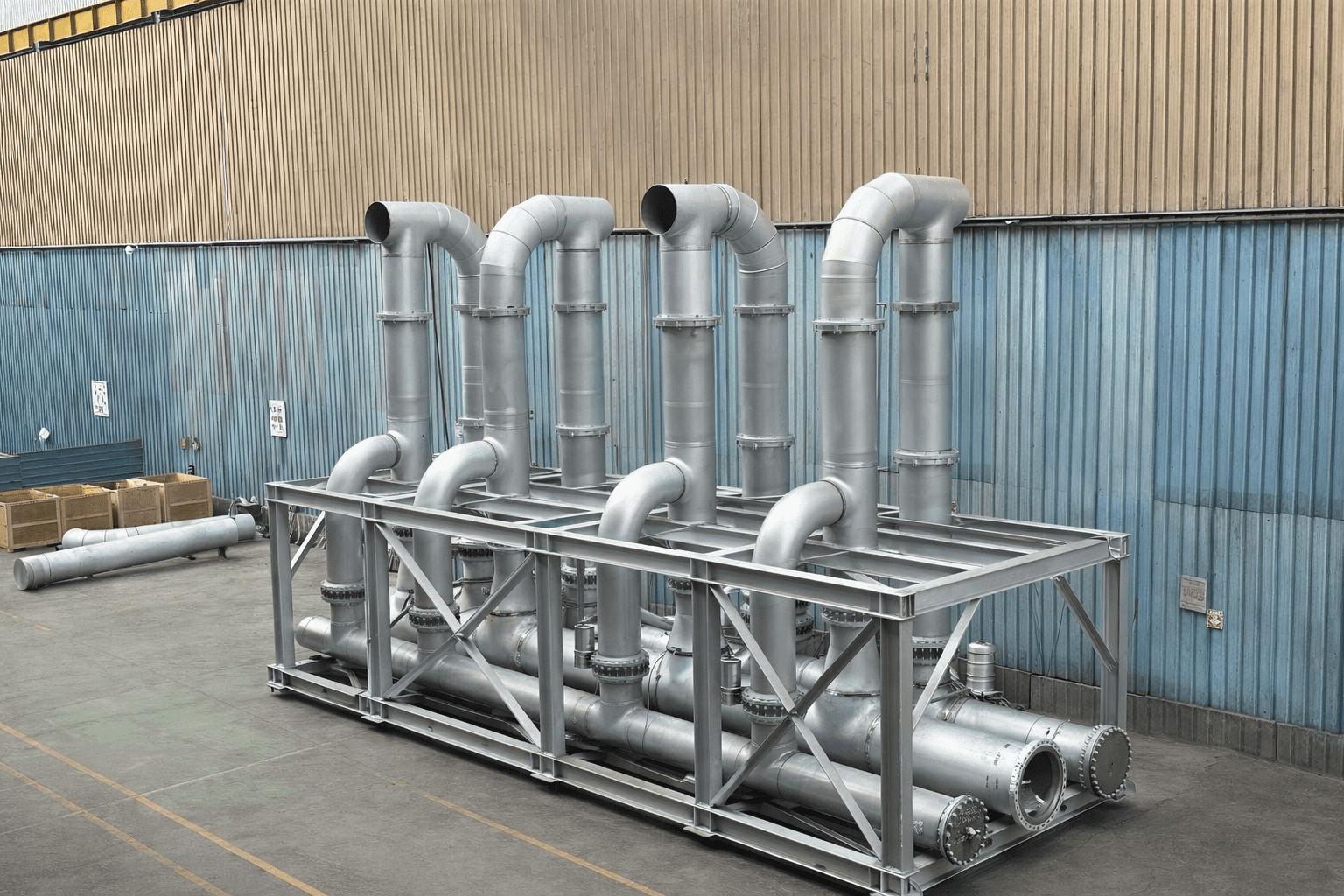

Handling Capabilities

Our facility is built to ensure seamless material handling during the fabrication and shipment of oversized and heavy-duty equipment.

- Cranes: Multiple overhead cranes up to 65-ton lifting capacity

- Maximum Shipment Size: Capable of handling single-piece shipment up to 5.5 m dia, 40 m long, 90-tons weight

- Proximity to Highway: Direct access to National Highway 8

- Proximity to Ports: Dahej, Hazira, Kandla, Mundra and Mumbai

Welding Capabilities

Our welding expertise is at the core of our fabrication quality, managed by certified professionals and advanced welding processes.

- Certified Welders: A pool of qualified welders (ASME, EN) for a wide range of materials

- Welding Processes: SAW, SMAW, FCAW, GTAW, GMAW

- Advanced Welding Processes: Column & Boom manipulator and semi automatic

Size & Materials Handled

We are experienced in working with a diverse array of materials and have the capacity for large-scale fabrication.

- Equipment Diameter: Up to 5.5 meters

- Equipment Length: Up to 40 meters

- Module Size: Up to 30m L x 6m W x 8m H

-

Materials Handled:

- Carbon steel including clad materials and low alloy steel

- Stainless steel (all grades)

- Duplex and Super Duplex

- Exotic Alloys (Inconel, Monel, Hastelloy, CuNi, Aluminium)

- Titanium

Third Party Inspection Agencies

We maintain excellent working relationships with all major third-party inspection agencies (TPIs) and are qualified to manufacture equipment under their surveillance.

Some of the leading TPIs we have worked with are:

- Lloyd's Register

- DNV (Det Norske Veritas)

- SGS

- BV (Bureau Veritas)

- TÜV

- IBR (Indian Boiler Regulations)